| Sensor |

Vanadium oxide (VOx) microbolometer |

| Wavelength |

Broadband MWIR/FIR: 2 to 16 µm |

| Pixel Count, H x V |

307 kilopixels, 640 x 480 |

| Image Area |

10.88 x 8.16 mm |

| Pixel Dimension |

17 x 17 µm |

| Min. Beam (10 pixels) |

~170 µm |

| Shutter Type |

Rolling |

| Max. Full Frame Rate |

30 Hz (7.5 for export) |

| Signal to RMS Noise |

≥1000:1 |

| Opt./Elec. dB |

30/60 |

| ADC |

14-bit |

| Measurable Sources |

CW beams, pulsed sources (auto-trigger sync) |

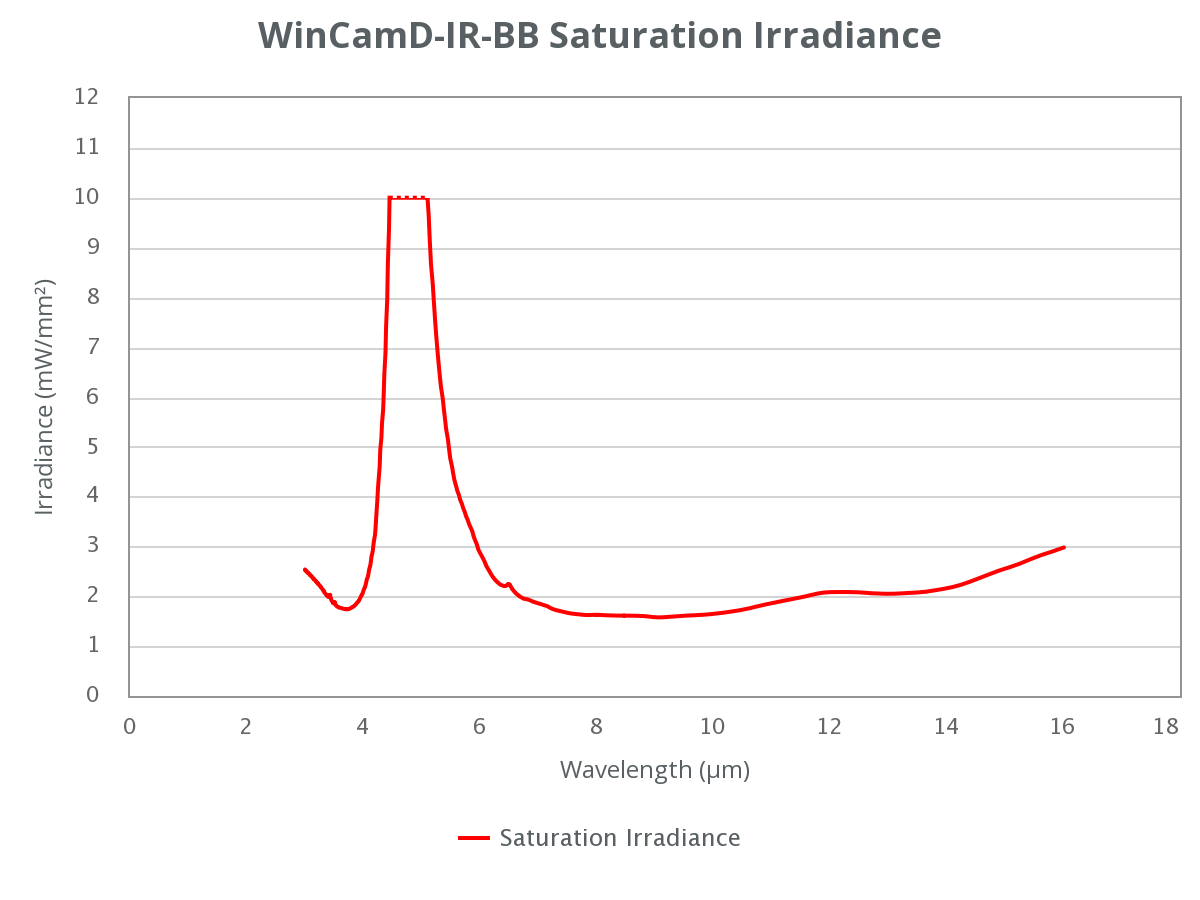

| Measured Beam Powers |

See the Approximate Saturation Power Limits graph |

| Manual Beam Attenuation |

Provided 1″ ND-1 and ND-2 reflective Germanium filters. See app note for more info. |

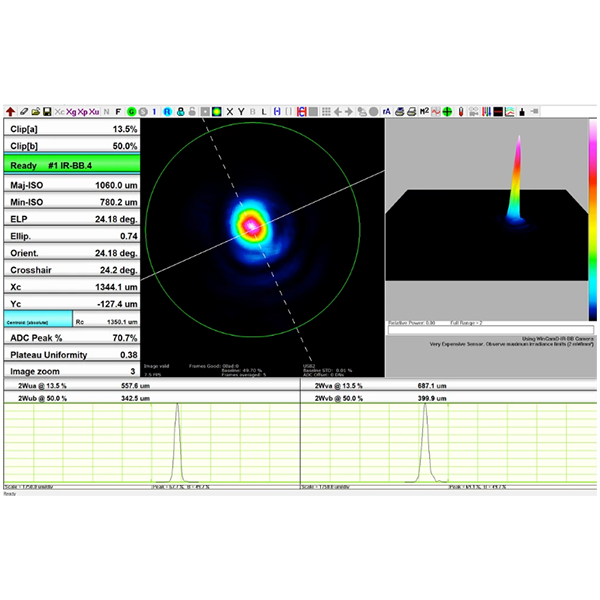

| Displayed Profiles |

2-D & 3-D plots

10, 16, 256 or max colours or grey. Contoured display at 10 and 16 colour. |

| Measured & Displayed Profile Parameters |

Raw and smoothed profiles

[Triangular running average filter up to 10% FWHM] |

| Beam Diameter |

Diameter at two user set Clip levels

Gaussian & Second Moment beam diameters

Equivalent diameter above a user defined Clip level

Equivalent Slit and Knife Edge diameters |

| Beam Fits |

Gaussian & Top Hat profile fit & % fit

Equivalent Slit profile |

| Beam Ellipticity |

Major, Minor & Mean diameters. Auto-orientation of axes. |

| Centroid Position |

Relative and absolute

Intensity Weighted Centroid and Geometric Centre

Beam Wander Display and Statistics |

| Measurement Accuracy |

5 µm processing resolution for interpolated diameters

Absolute accuracy is beam profile dependent – ~10 µm accuracy is frequently achievable

Centroid accuracy is also beam dependent. It can be as good as ±10 µm since it is arithmetically derived from all pixels above the centroid clip level. |

| Processing Options |

Image & profile Averaging, 1, 5, 10, 20, Continuous.

Background Capture and Subtraction.

User set rectangular Capture Block for capture

User set or Auto ellipse Inclusion region with beam tracking for processing

*.ojf files save all WinCamD custom settings for particular test configurations |

| Pass/Fail display |

On-screen selectable Pass/Fail colours. Ideal for QA & Production. |

| Log data and statistics |

Min., Max., Mean, Standard Deviation, to 4096 samples |

| Relative Power Measurement |

Rolling histogram based on user’s initial input. Units of mW, µJ, dBm, % or user choice (relative to a reference measurement input) |

| Fluence |

Fluence, within user defined area |

| Certification |

RoHS, WEEE, CE |

| Multiple Cameras |

Up to 4 cameras, parallel capture.

1 to 8 cameras, serial capture. |

| Camera Dimensions‚ Width x Height x Depth |

73 x 73 x 52 mm |

| Optical depth from housing/filter to sensor ±0.2 mm |

15.5 mm |

| Mounting |

1/4″-20 holes aligned with sensor centre |

| Weight (Camera with 1″ NDL-2 Ge filter) |

422 g) |