This piece covers optical density, daylight transmission (VLT), and colour vision.

Laser Safety Filter

Due to the unique characteristics of laser radiation (i.e. coherent, collimated and monochromatic) there is a serious risk to potentially harming your vision. Therefore special optical filters that transmit ‘normal’ light but block laser light must be used.

Since laser light has a specific wavelength which is dependent on the laser active medium that emits light, protective filters that match the wavelength and power of the specific source of laser radiation are needed. When wearing laser safety glasses or looking though laser safety windows some wavelengths of the spectrum that would normally reach our eyes are filtered out. This means, if light from the visible region is blocked, this will inevitably change the perception of the environment as well. First, by attenuation of the transmission the environment gets darker (similar to the effect of sun glasses). Second, blocking some wavelengths changes our perception of colour. Therefore a careful choice of the fitting laser safety filters and their technology is a challanging task. The correct choice depends on an accordance between the calculated laser safety ratings and the requirements of the particular application. The very important physical characteristics of laser saftey filters are:

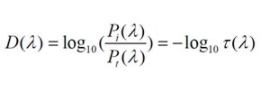

Optical Density

The Optical Density (OD or D(λ)) is the attenuation of light that passes through an optical filter. The higher the OD value, the higher the attenuation. The mathematic expression of Optical Density D(λ) is the logarithm to the base ten of the reciprocal of the transmittance and is given by the listed equation (where τλ is the transmittance).

In other words, the Optical Density is a measure that indicates how many decimal places the transmission shifts at the required wavelength. But according to the above described standards the Optical Density alone is not sufficient enough to guarantee protection against laser radiation. It is important that the Optical Density will also remain high enough in case of a direct laser hit on the filter.

This requirement seems to be trivial, but there are indeed some interaction effects of filter and laser radiation, which can cause some reduction of the Optical Density.

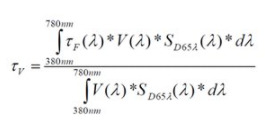

Daylight Transmission (VLT)

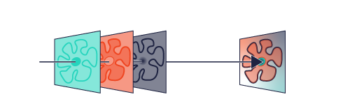

The attenuation of light by a filter with the transmission τF (λ) in the visible spectrum is defined by the so-called VLT (visible light transmission) the daylight transmission or the luminous transmittance (short: τV). The VLT (τV) is determined in relation to the standard illuminant D65 (see ISO/CIE 10526:1991 and ISO/CIE 10527:1991) and evaluated according to the spectral sensitivity of the eye to daylight (V(λ).

Should the measured VLT-value be less than 20 %, the user should ensure that their working environment receives additional illumination (EN 207). With a low VLT and bad illumination one can expect our eyes to adapt to so-called night vision. In doing so, the colour vision is restricted and the spectral sensitivity of the eyes VN(λ) moves towards the shorter wavelengths. For these kinds of filters it is also useful to provide the VLT-value for night vision.

Colour Vision

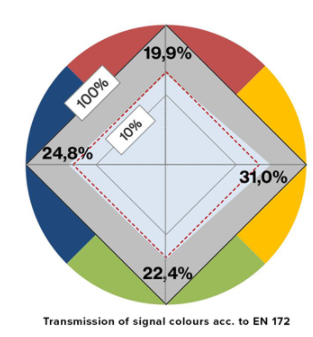

The eyes can adapt to different light situations and the total amount of light can be balanced by additional illumination. Therefore another important aspect for the selection of a laser safety filter is colour vision. If colour vision is impaired or restricted, some colours may not be recognised. This effect may also apply to warning lights or displays, or the ability to distinguish between instruments or vessels marked by colour such as those found in medical surroundings.

laservision visualises the colour view by means of a special diagram (i.e. laser safety filter P1E07) based on the standard EN 172 (signal light recognition). This standard defines, subject to the VLT, the minimum transmittance of a laser safety filter at the four basic colors red, green, blue, and yellow to meet the requirements of the signal light recognition. This threshold value is illustrated in the diagram by the dashed line in red. The transmission values of the filter which are obtained in reality are specified at every axis. The larger the light blue color area and the more symmetric the form, the better is the brightness value and the color perception of the laser safety filter.

This article was sourced form our laser safety partner, laservision GmbH & Co,

Laser Safety Calculation Form

Complete our laser safety calculation form to get specifications on the laser safety goggles you will need.

Laser Safety Product Category

Head over to our laser safety product category to see our vast range of laser safety products and accessories.

Other Blogs/Articles that may be of interest:

- Why is Mid-IR Light so Important?

- Engineered Point Spread Functions (PSF) for Single Molecule Localisation Microscopy (SMLM)

- Nanoscopy for less than £100k?

- Understanding the jargon of LCOS Spatial Light Modulators (SLMs)

- Spatial Light Modulator Applications

For more information, contact us here: