Including the Frost & Sullivan (F&S) Technology Award and the Platinum Award of Lasers & Sources from Laser Focus World.

NUBURU’s high-power blue lasers have done it again. Adding to last year’s awards, NUBURU have been presented with the Frost & Sullivan award for Technology Innovation and the Platinum award for Lasers & Sources from Laser Focus World. Both organisations released a press release, see what they had to say:

Frost & Sullivan:

Its high power and brightness allow it to weld copper, aluminum, and dissimilar metals in a defect-free, spatter-free manner

SANTA CLARA, Calif. — November 25, 2019 — Based on its recent analysis of the North American high-power blue lasers market for copper welding, Frost & Sullivan recognises NUBURU, Inc. with the 2019 North American Technology Innovation Award for being the first company to have developed a blue laser technology for welding copper and dissimilar alloys.

It is a high-power laser comprising gallium nitride semiconductor laser diodes operating in the blue wavelength coupled to an optical fiber. This technology is highly useful in applications ranging from automotive electric vehicles (EVs) to consumer electronics module manufacturing within smartphones, laptops, and desktops.

In 2018, NUBURU commercialised its blue laser technology in the form of the 150 Watt AO-150 and 500 Watt AO-500 products for industrial applications. Though conventional industrial lasers are powerful, reliable, and automated, they operate in the IR region with a wavelength of about 1 to 10 microns (µm), which is inadequate to efficiently weld copper. The blue laser technology operates at a wavelength of 450 nm, which makes it well suited for welding copper and other metal alloys with a material thickness of up to 700 microns (µm). The physics of blue light allows copper to absorb 13 times more light than possible with IR light, resulting in a quicker melt of the copper material and keyhole mode welds.

“The AO-500 blue laser technology has a processing power equivalent to a 5 kilowatt IR laser, without reaching the vaporization stage or creating bubbles inside the weld. This results in a mechanically strong and spatter-free, defect-free weld,” said Ranjana Lakshmi Venkatesh Kumar, Industry Analyst. “By adopting high-power blue laser diodes, developing micro and macro optics solutions, and integrating these with an optical fiber to produce a laser beam similar to conventional industrial lasers, NUBURU presents a differentiated blue laser technology to the welding industry.”

NUBURU is especially focusing on increasing its laser’s power from 500 Watts to 1kW-4kW so it may be used to weld materials with a thickness of 2mm to 5mm. It is also investing resources in developing brighter lasers. The brighter the laser, the smaller the spot size, which generates a deeper, stronger, and thinner weld. NUBURU’s near-term aim is to provide a laser power source that is two times more powerful than other blue energy sources, enabling a 60 percent deeper penetration of the weld.

“Significantly, NUBURU is targeting the high-potential 3D printing metal market. As blue laser technology can provide 10 times faster build rate and results in high-resolution net-shape parts, the solution is expected to experience high adoption in this large, demanding market,” noted Kumar. “NUBURU caters to a key future need in welding by ensuring improved productivity and resolution via blue light lasers. Frost & Sullivan recognizes its foresight of identifying a vital industry need and addressing it with its timely blue light laser technology.”

Each year, Frost & Sullivan presents this award to the company that has developed a product with innovative features and functionality that is gaining rapid acceptance in the market. The award recognizes the quality of the solution and the customer value enhancements it enables.

Frost & Sullivan Best Practices awards recognize companies in a variety of regional and global markets for demonstrating outstanding achievement and superior performance in areas such as leadership, technological innovation, customer service, and strategic product development. Industry analysts compare market participants and measure performance through in-depth interviews, analysis, and extensive secondary research to identify best practices in the industry.

About Frost & Sullivan

For over five decades, Frost & Sullivan has become world-renowned for its role in helping investors, corporate leaders and governments navigate economic changes and identify disruptive technologies, Mega Trends, new business models and companies to action, resulting in a continuous flow of growth opportunities to drive future success.

This article was sourced from Frost & Sullivan.

Laser Focus World:

LASERS & SOURCES | AO-500 High Power High Brightness Blue Laser

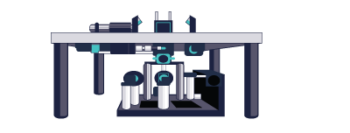

The AO-500 is a fiber-delivered high-power high-brightness blue laser that delivers a minimum of 500 W CW at 450 nm with full modulation up to 500 Hz. Due to high absorption in the blue, the AO-500 enables welding yellow metals spatter-free, dramatically improving the mechanical and electrical performance of welds and joints. Offering high quality and low to spatter-free welding of yellow metals such as copper and gold, the AO-500 dramatically improves process performance. The 400 µm fiber includes a QBH connector and is available with a suite of welding lenses, making it a complete welding optomechanical solution for customers.

This article was sourced from Laser Focus World.

Other Blogs/Articles that may be of interest:

- Why is Mid-IR Light so Important?

- Engineered Point Spread Functions (PSF) for Single Molecule Localisation Microscopy (SMLM)

- Nanoscopy for less than £100k?

- Understanding the jargon of LCOS Spatial Light Modulators (SLMs)

- Spatial Light Modulator Applications

Contact us here: