Extended Contact Ball Bearing Guide Method (GOHT/GOHTA Series)

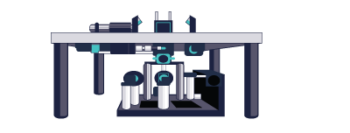

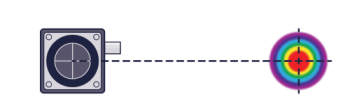

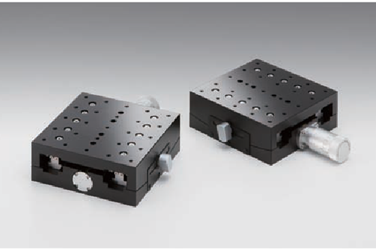

GOHT steel micrometer-driven EXC™ Precision-Bearing goniometers are an absolute marvel of translation stage engineering. They are the first and only goniometer to feature curved EXC™ precision bearing ways that are processed directly into the body and base. This construction results in the highest stiffness, load capacity and smoothness of any stage on the market. The EXC™ patented bearing technology also provides the GOHT with low-friction, high-resolution movement as well as rotation axis displacement that is 1/10th the magnitude of dovetail bearing goniometers. As with all goniometers, the axis of rotation is situated parallel to and above the mounting platform but they are also designed to be stacked so to have intersecting orthogonal axes of rotation. In this configuration, they have capability for orbit-like positioning about a single point. This family of GOHT stages are micrometer driven for recordable movements and include a carriage lock. All are made entirely from hardened tool steel and are plated with an RoHS-Compliant black chrome.

GOTHA goniometers are large platform all-aluminum stages with exceptionally high rotation-axis heights, the largest being 228 mm (almost 9 inches high). They are driven by a high-tolerance worm-gear mechanism which, along with its high precision ball-bearing guides, yields angular position readable to 1 arc minute using the vernier scale. As with all goniometers, the axis of rotation is situated parallel to and above the mounting platform but they are also designed to be stacked so that they have intersecting orthogonal axes of rotation. In this configuration, they have capability for orbit-like positioning about a single point. The GOTHA series of goniometers are lockable and finished in a RoHS-compliant black anodize.

Features:

High precision, high load capacity and high stiffness.

High Load Capacity and High Stiffness

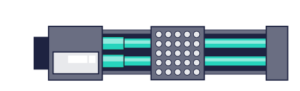

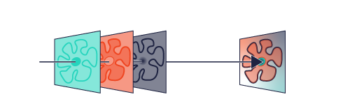

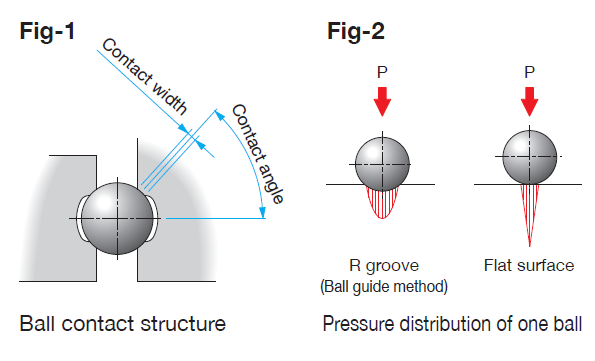

- The four-array contact structure achieves high load capacity and high stiffness (13 times stiffer than the V groove) As shown in Fig-1, ball guides are machined across the arcs so that they have R groove structure and good contact with a ball allowing stable load capacity against the load in the directions where contact with the ball occurs frequently.

High Durability

- Long life and free of maintenance Fig-2 shows the pressure distribution of the R groove and the flat surface. As shown in the figure, pressure exerted on the R groove is dispersed and does not reach inside. Thus, metal fatigue and wear are reduced. Data for durability is listed. E015

High Precision

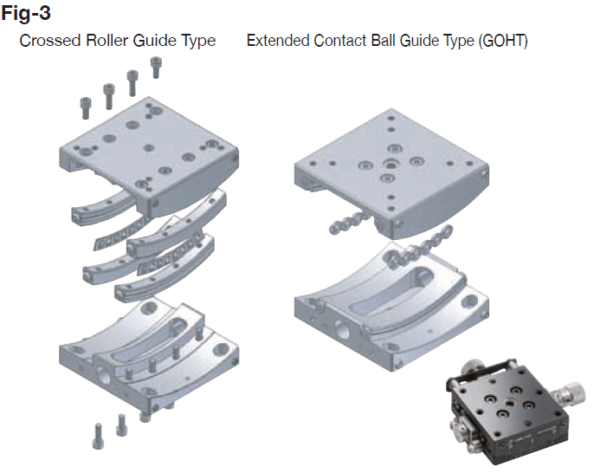

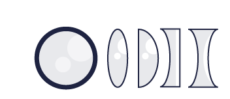

- Our original processing technology achieved an integral structure of the main body and the guides. As shown in Fig-3, because the crossed roller type goniometer stage, which has been the mainstream, has the guide

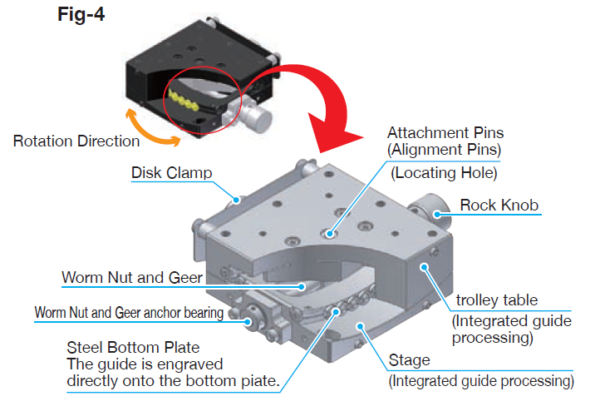

separate from the main body, there are many parts. Assembling a large number of parts caused errors or variation, resulting in translation errors, that is, deviation in the most important rotation center when the stage moved. Our goniometer stage as shown in Fig-4, has the guide integrated into the main body in order to compensate for assembly errors or variation by machining accuracy. With the integral structure, the displacement of the rotation center is reduced.