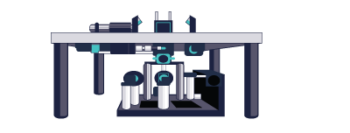

- 40 mm and 60 mm centre of rotation options allow for two axes of motion about a common centre of rotation

- 30 N load capacity

- Low profile, small footprint

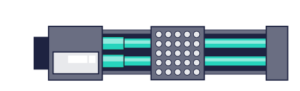

- Designed for use with an X-MCC Series stepper motor controller or any 2-phase stepper motor controller

- With Auto Detect, the X-MCC controller configures its settings automatically for the connected peripheral

Features:

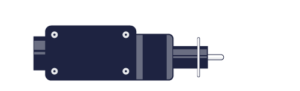

1. 200 step per revolution stepper motor, microstepped up to 256x to provide smooth and precise motion.

2. Crossed roller bearings for smooth motion and high stiffness.

3. The interlocking alignment system makes it easy to stack two stages.

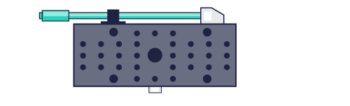

4. M2 (20 mm pattern) and M3 (32 mm pattern) mounting holes provided.

5. DB15 male connector for quick connection and automatic detection with Zaber Technologies’ X-MCC single or multi-axis controllers.

6. The GSM60 and the GSM40 stages can be stacked together to share a common centre of rotation, 40 mm above the top stage.

7. A shaft-mounted knob for coarse positioning without power.

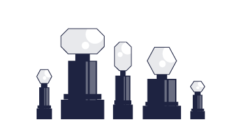

Zaber Technologies’ GSM Series devices are motorized goniometers with high thrust and speed capabilities in a compact package. They are stepper motor driven positioning goniometers designed to interface with our X-MCC controllers, offering high resolution daisy-chainable operation.

Set up is easy with Auto Detect. Once connected, the X-MCC controller will automatically detect and configure the GSM. These stages are excellent for applications where a small profile is required. They can mount to a flat surface or stack together to share a common centre of rotation for two axes of angular motion.