High Speed Spatial Light Modulators 1024×1024

The High Speed Spatial Light Modulators are available as high speed , with or without a dielectric mirror, or with or without temperature control. Please see the specifications and options tabs for further details.

This high speed SLM supports frame rates up to 1436.1 Hz.

Below are some details about Meadowlark’s SLM.

Key Features

- High resolution

- High speed – frame rates up to 1436.1 Hz

- High Phase Stability – 0.2 – 1.0%

- Pure analog phase control

- High first order efficiency

- High reflectivity

- High power handling

- On-board Memory

- Wavelengths from 488 – 1650 nm

High Speed with High Phase Stability – Great care was taken in the design of the 1024 x 1024 silicon backplane to enable high speed operation while simultaneously maximising phase stability. Engineers successfully achieved high speed without compromising phase stability. The 1024 x 1024 SLM is incredibly fast with liquid crystal response times ranging from 0.6 to 8 ms (wavelength dependent) for a full wave of modulation when running in typical room temperature environments.

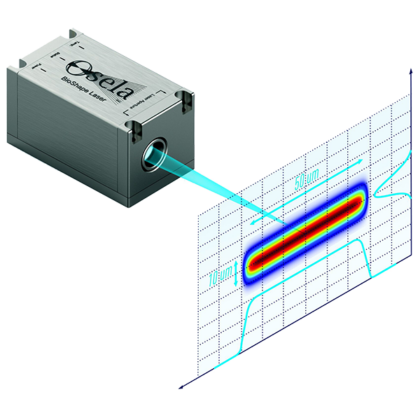

Liquid Crystal on Silicon (LCoS) Spatial Light Modulators (SLMs) are uniquely designed for pure phase applications and incorporate analog data addressing with high refresh rates. This combination provides users with the fastest response times with high phase stability. The 1024 x 1024 SLM is good for applications requiring high speed, high diffraction efficiency, low phase ripple and high-power lasers.

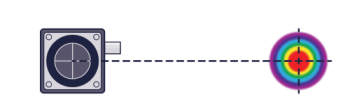

High Phase Stability – Making an LCOS SLM faster usually means the phase stability becomes worse. However, we’ve combined our traditional analog drive scheme with some new proprietary technologies to suppress phase instabilities to an unprecedented 0.2 – 1.0% without compromising the speed. Phase ripple is quantified by measuring the variation in intensity of the 1st order diffracted spot as compared to the mean intensity while writing a blazed phase grating to the SLM.

High Efficiency Dielectric Mirror Coating – All the light reflecting off the SLM is modulated – including the light between the aluminium pixel electrodes. The reflective pixel structure associated with a LCoS SLM backplane acts as an amplitude grating diffracts some light into higher orders. Optically, the active area of the backplane is converted into a flat dielectric mirror by depositing dielectric layers to eliminate the amplitude and optical path variations associated with the underlying aluminium pixel structure. The dielectric stack is kept thin to minimise any drop in electric field across the LC layer. In other words, there are no abrupt changes in phase modulation (such as dead zones) between pixels due to the smoothing which results from separating the LC modulator from the driving electrodes.

Software – Meadowlark Optics’ SLMs are supplied with a graphical user interface and software development kits that support LabVIEW, Matlab, Python, and C++. The software allows the user to generate images, to correct aberrations, to calibrate the global and/or regional optical response over ‘n’ waves of modulation, to sequence at a user defined frame rate, and to monitor the SLM temperature.

Software Feature

- Input and Output Triggers

- Image Generation

- Automated Sequencing

- Wavefront Calibration

- Global and Regional Look Up Tables

- Temperature Monitoring

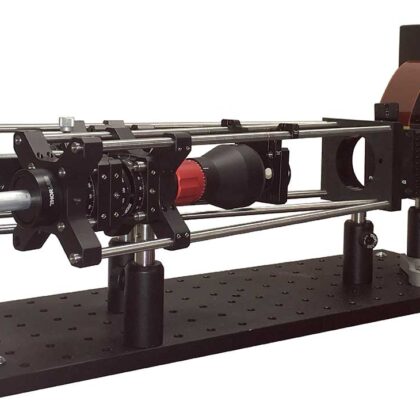

Hardware Interface – The 1024 x 1024 SLM system includes a Gen3 x8 PCIe controller with input and output triggers and low latency image transfers. Triggering can be performed on SLM chip refresh period boundaries of 696 µs, or even in the middle of refresh periods for applications requiring the SLM be tightly synchronized to external hardware. The controller also includes 752 frames of internal memory that can be loaded in advance, then sequenced at full speed in order to minimise traffic on the PCIe bus during operation.